產品介紹項目

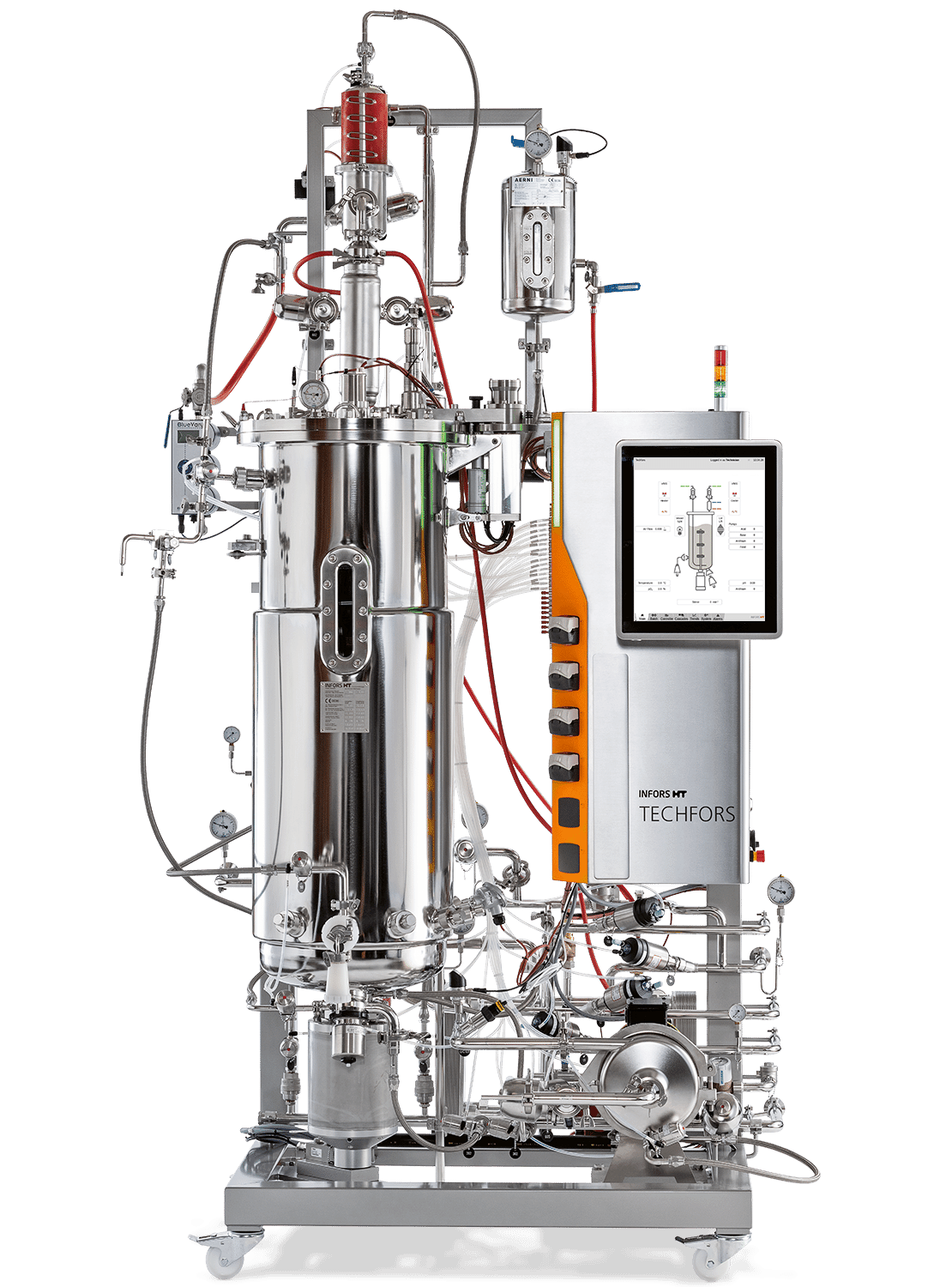

Pilot Bioreactors Techfors

產品介紹:

There are practically no limits on flexibility with regard to design and operation, since each pilot bioreactor model is built individually according to your needs. You specify the requirements – we implement them after performing a thorough feasibility study.

產品搜索:

規格訊息:

Techfors

Pilot bioreactor for sophisticated bioprocesses

| Stainless steel vessel | Working volume up to 660 L |

| Double jacket made of 316L stainless steel | |

| Individually configurable with a selection of different impellers, spargers and special accessories | |

| Individually configurable no. ports for sensors (anti-foam, optical density, pH, pO2, redox, conductivity, live cell density, etc.) | |

| Pivoting vessel lid for easy access as an option | |

|

|

Easy movement of the device possible with stable wheels (up to approx. 300 L)

|

| High-performance pumps | Basic setup includes four precision pumps per culture vessel (option of one more) |

| Gravimetric feeding (with external scale) | |

|

|

Profile-based pump-speed control with eve®

|

| Gassing | Customer-specific gassing |

| Feed via rotameter or mass-flow regulator | |

| Cascades may be configured in serial or in parallel for controlling the pO2 via the stirrer speed, gassing rate, gas composition, etc. | |

|

|

pH control with acid and CO2

|

| Sensors | Customers may choose from digital (Modbus) or analog sensors. |

| Product calibration of the pH sensor for reliable measurements during long-running bioprocesses | |

|

|

If required, additional sensors and actuators can be connected.

|

| Sterilisation | in-situ sterilisation |

|

|

Mains steam or steam generator (external or integrated in the basic unit)

|

| Validation & qualification | Meets FDA requirements |

| Meets GMP guidelines | |

|

|

Qualification options: IQ/OQ/FAT/SAT

|

| Operating unit | Reliable measurement and setting of the bioprocess parameters and communication with eve® |

|

|

Up to 24 selectable parameters, such as temperature, stirring speed, pH, pO2, anti-foaming agent, feed

|

| eve® Bioprocess Platform Software | Planning, controlling and analysing bioprocesses |

| Integrated workflows, devices and bioprocess knowledge | |

| Integrates bioreactors and analytical instruments, regardless of the manufacturer | |

| Web-based project organisation | |

| Communication using the latest OPC UA (Minifors 2) or OPC XML-DA standard (Multifors 2, Labfors 5, Techfors-S, Techfors) | |

| Synchronisation of process-related events such as sampling or inoculation |

|

Vessels

|

up to 1000 L

|

|---|---|

|

Working volume

|

up to 660 L

|

|

Dimensions (W x D x H)

|

Depending on specification

|

|

Drive

|

Depending on specification

|

|

Temperature

|

up to 90 °C for temperature control; up to 135 °C for sterilisation

|

|

Gassing per vessel

|

Depending on specification

|

|

Pumps per vessel

|

3 fixed, 1 variable, optional 1 additional

|

|

Ports per vessel

|

Depending on specification

|

|

Connectivity

|

OPC XML DA via Ethernet

|

|

Parallel operation via touch screen controller

|

n/a

|

|

Sterilisation

|

Sterilisation-in-Place

|

產品影片:

詢價車:

- Part NO.

- Qty

- Inquiry

- Techfors