產品介紹項目

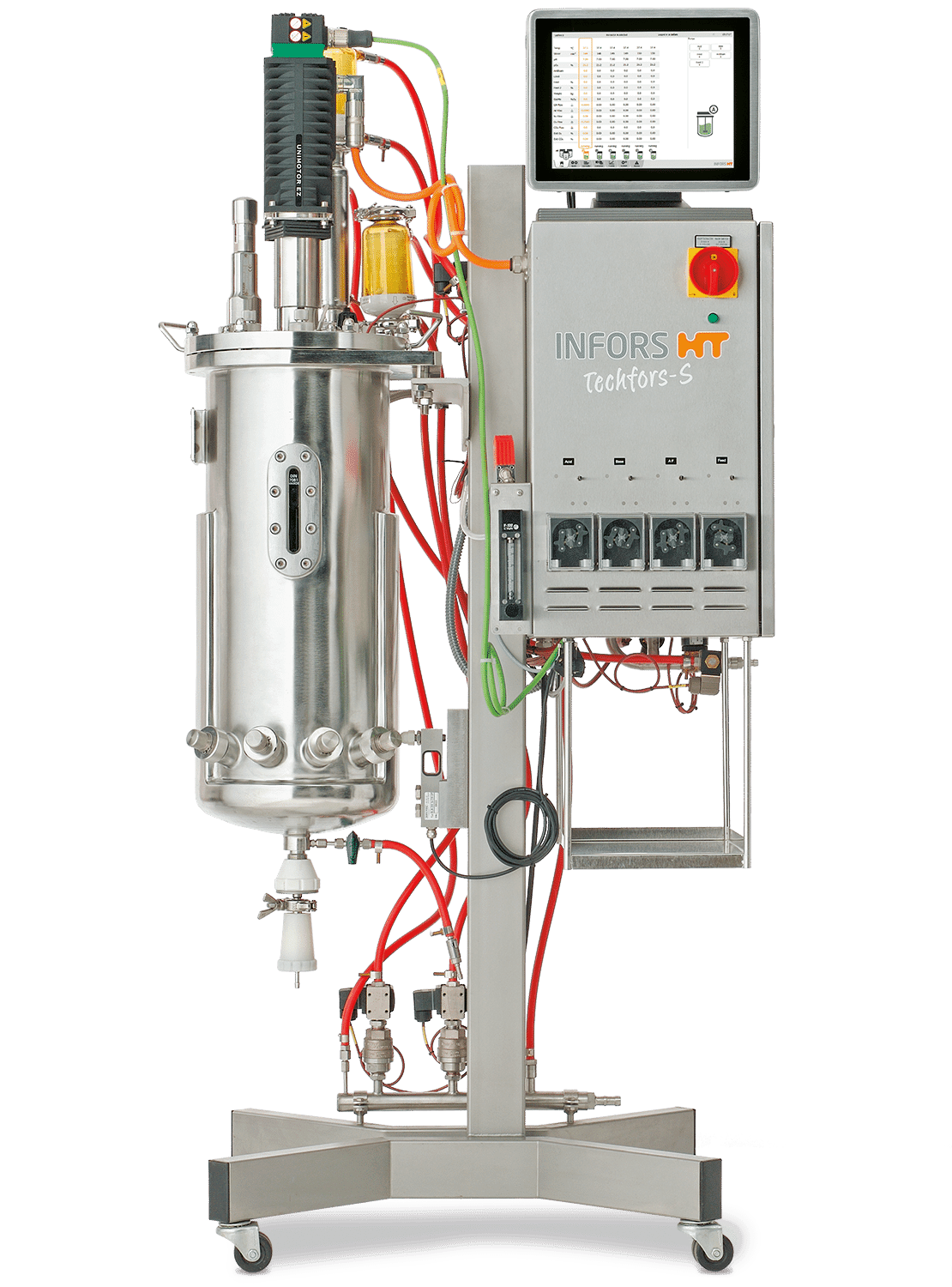

Techfors-S

產品介紹:

Is the first step always the hardest? Not with the Techfors-S. The Techfors-S contains exactly the same components as our bench bioreactors. This ranges from the pumps via the gassing line to the touch screen controller and the associated software. Both beginners as well as process experts will be able to manage easily

產品搜索:

規格訊息:

Techfors-S (Working volume from 3 to 30 L)

| Vessel |

|

|

|

|

|

|

|

|

|

|

| High-performance pumps |

|

|

|

|

|

|

|

|

| Gassing |

|

|

|

|

|

|

|

|

| Sensors |

|

|

|

|

|

|

| Sterilisation |

|

|

|

|

| Operating unit |

|

|

|

|

|

|

|

|

| eve® Bioprocess Platform Software |

|

|

|

|

|

|

|

|

|

|

|

Vessels

|

15 L / 30 L / 42 L

|

|---|---|

|

Working volume

|

3–10 L / 5.3 L–20 L / 6–30 L

|

|

Dimensions (W x D x H)

|

1017 mm x 934 mm x 1841 mm

|

|

Drive

|

Direct drive to 1200 min-1 Magnetic drive to 300 min-1 (Zellversion) |

|

Temperature

|

Coolant temperature + 5 °C to 80 °C; to 130 °C for sterilisation

|

|

Gassing per vessel

|

up to 3 MFCs

|

|

Pumps per vessel

|

3 fixed, optional 2 additional variable

|

|

Ports per vessel

|

Top plate: Vessel bottom: |

|

Connectivity

|

OPC XML DA via Ethernet

|

|

Parallel operation via touch screen controller

|

-

|

|

Sterilisation

|

Sterilisation-in-Place

|

產品影片:

詢價車:

- Part NO.

- Qty

- Inquiry

- Techfors-S